What We Do

As mechanical innovators, the combination of 3D design, computational analysis and verification, prototyping, and failure assessments are something that our mechanical engineering team excel at.

Mechanical Design and Analysis

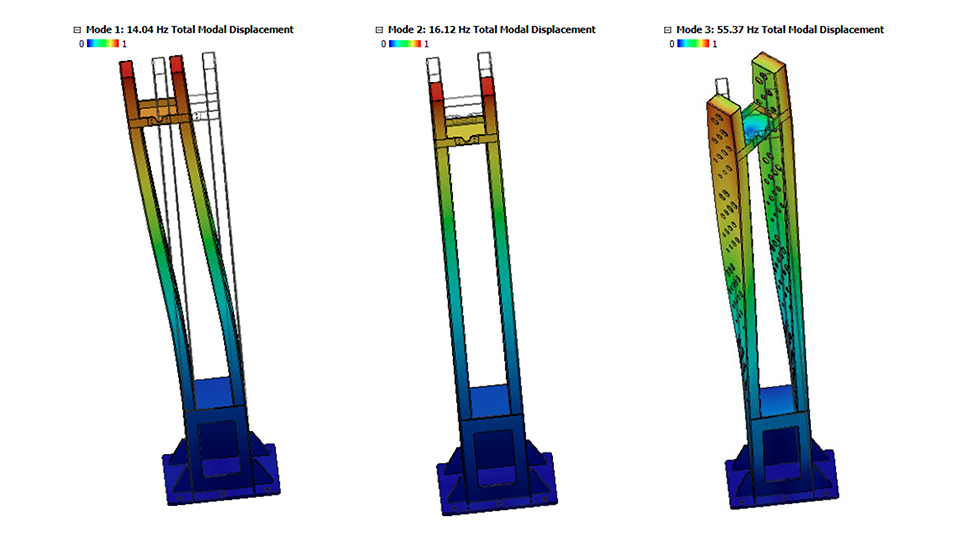

Our Mechanical Design and Analysis services are foundational to our engineering work. We specialise in 3D CAD modelling, machine component design, sheet metal design, drafting, and engineering strength analysis (FEA). Our expertise ensures designs that meet all relevant standards and perform reliably under real-world conditions.

Product Development and Innovation

We bring your ideas to life through our Product Development and Innovation services. From concept and design to prototyping and production, we ensure your products are both innovative and market-ready. Whether you're a startup, an established company, or looking to improve an existing product or system, we provide the support needed to turn concepts into successful solutions.

System Optimisation and Component Replication

We can assist in fine-tuning existing mechanical systems to improve performance and extend their lifespan. If any parts are worn out or no longer available, we use advanced 3D laser scanning to create accurate replacements. This ensures your systems stay operational and reliable.

Failure Analysis, Investigation, and Reporting

Our Failure Analysis and Investigation services delve into the root causes of issues, using advanced techniques such as fatigue analysis to predict past and prevent future failures. We provide comprehensive reports detailing our findings and recommending corrective actions, helping you make informed decisions to improve system performance.

Manufacturing Support

Our Manufacturing Support services encompass the entire production process, from material sourcing to final assembly. We conduct thorough design reviews using methodologies such as DFMA and DFMEA, ensuring your designs are optimised for cost and reliability. We also assist in setting up strict quality control processes to guarantee that your products meet the highest standards. Our goal is to streamline the manufacturing process, helping our clients reduce unnecessary expenses and focus on innovation.

Compliance and Documentation Services

Our Compliance and Documentation services include design validation, certification, and independent design reviews. We also create detailed operational manuals, maintenance schedules, and other essential documentation to support the effective management and operation of machinery or systems, ensuring your project meets all regulatory requirement

Our Team

Ben heads up our Mechanical Engineering team at Covey, supported by Stephen Braiden, Kevin Covey and the Civil team.

Ben Polson

Lead Senior Mechanical Engineer

- Ben, BEng(Mech)(Hons)

Ben brings broad mechanical engineering experience across the UK and Australian markets, with a background spanning building services and high integrity defence projects. His career includes key design roles in nuclear process environments within the UK defence industry, where he gained experience in technically demanding and highly regulated design settings. Ben has a strong foundation in structured design processes, 3D CAD modelling, detailed mechanical systems design and multidisciplinary coordination. He also offers hands-on project management capability, having led design teams through all stages of the project lifecycle, from concept through to construction and commissioning. His combination of technical depth and practical delivery experience enables him to lead projects with a focus on quality, efficiency, and integrated outcomes.

Stephen Braiden

Senior Mechanical Engineer

- BEng(Mech)(Hons)

Stephen is a highly experienced and adaptable Mechanical Engineer. He manages the mechanical engineering team at Covey and is highly experienced in managing mechanical projects from concept through to on-site commissioning.

Stephen has extensive experience in the use of engineering software such as Autodesk Inventor, Autodesk Fusion 360 and Spacegass, and is highly skilled in 3D CAD modelling and drafting. He is also has experience using the finite element method for linear and non-linear analysis, buckling analysis, dynamic modal analysis, dynamic event simulation, thermal analysis and topology optimization.

Stephen is a hands-on mechanical engineer, designing, building and testing prototypes to prove theories. Stephen also manages the Covey workshop where the mechanical team are set up to do basic manufacturing, assembly and testing. Stephen is skilled with RAMS assessment tools such as FMECA and FTA, as well as developing risk management studies.

Stephen’s work takes him across our disciplines, particular with his skills in FEA.